Natural rubber has been well-known for its resilience material property in providing seismic isolation for civil engineering structures over the past few decades. However, rubber on its own, possesses very little material damping under shear. This is the main reason that in EN15129, a rubber bearing can be regarded as possessing high damping capability when ξb(100 %) > 6%.

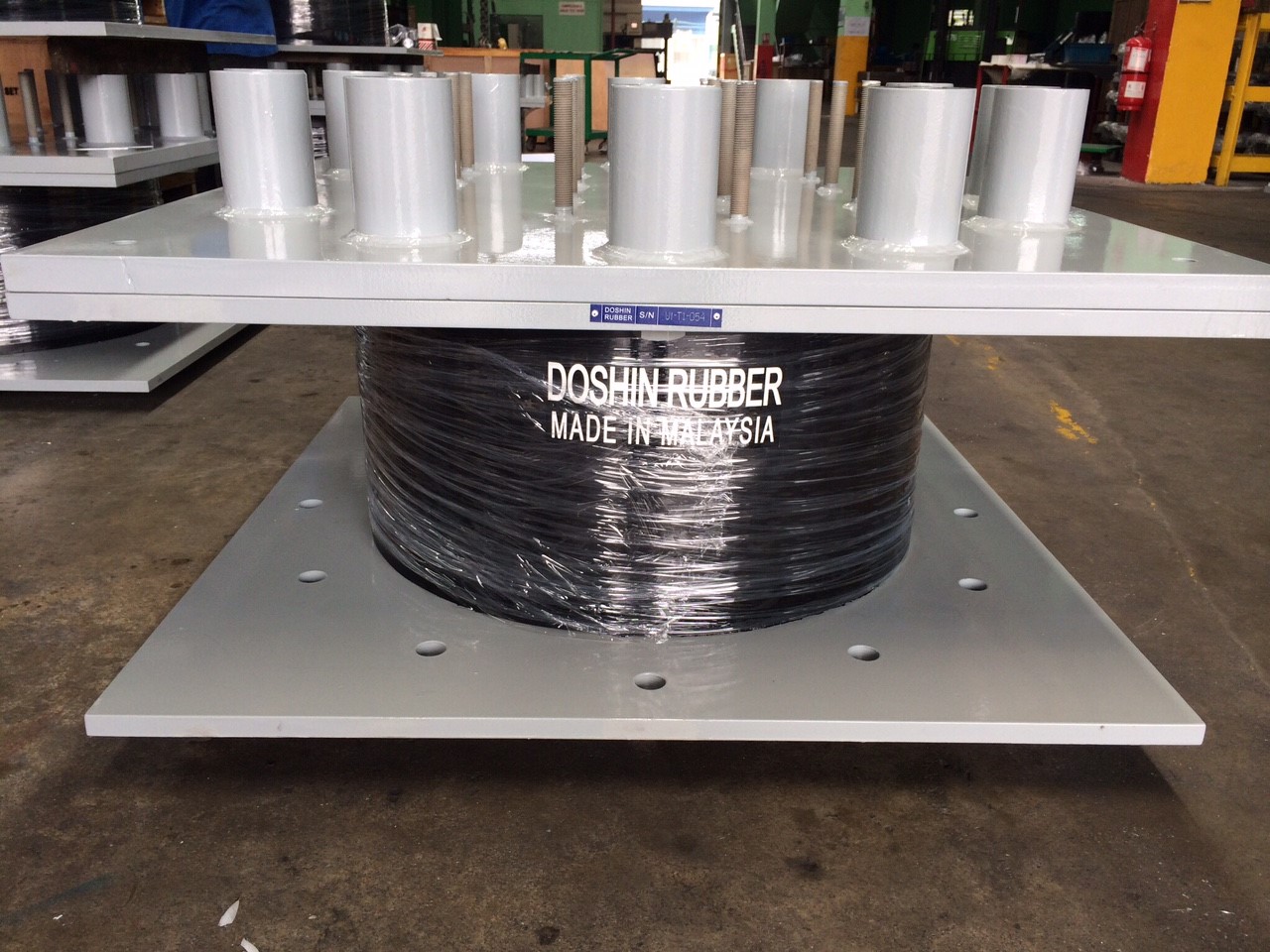

For long span structure such as bridges, higher damping is usually beneficial in reducing the seismic demand. In the past, lead was plugged into low-damping rubber to increase the composite hysteresis damping of a lead rubber bearing (LRB). Today, with our R&D capability, Doshin can developed material > 12% damping at design shear strain, which is equivalent to those achievable by LRB. This ultra-HDRB, uses nothing but natural rubber only which has been subjected to all the required mechanical and dynamic testing to ensure its durability, reliability and performance.

The u-HDRB has been used successfully in seismic isolation of a hospital and an office tower in Jakarta, Indonesia, Dong Thap Bridge, Vietnam, Laoag By-Pass Bridge, Phillipines, etc at a negligible cost difference compared to the conventional HDRB.

For more information, please get in touch with us at: 603-3290 5619 / 603-3290 5621 or click here for enquiry us.