Doshin Spherical bearings are designed for very high vertical, horizontal and lateral loads and where large rotational structural displacements need to be accommodated.

Operating principle

DOSHIN® SPHERICAL bearings are designed to transmit vertical forces in the bridge sub-structure and to facilitate rotations by means of a calotte and a concave lower part.

The flat sliding surface between the top of the calotte and a sliding plate accommodates longitudinal and transverse movements. Guide bars and a restraining ring are used to transmit horizontal forces.

Depending on whether the bearing is fixed, guided or free sliding, it accommodates vertical loads, horizontal forces, rotations and longitudinal or transverse movements.

Quality

Main reasons for the quality and durability of the bearings:

- Qualified and experienced specialised staff

- Sophisticated and reliable individual component

- High-quality materials: min. 8mm thick DR SLIDE sliding material, long-lasting silicone grease, etc

- Quality standard (certified to ISO9001)

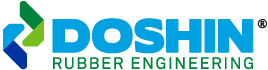

DSF (fixed)

The fixed bearing accommodates horizontal forces and rotations from any direction.

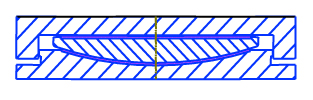

DSG (guided sliding)

The fixed bearing accommodates horizontal forces and rotations from any direction.

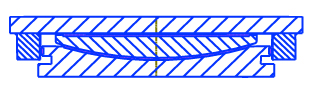

DSA (free sliding)

The free sliding bearing is movable and can be rotated in all directions and therefore cannot accommodate any horizontal forces.

Operating principle

DOSHIN® SPHERICAL bearings are designed to transmit vertical forces in the bridge sub-structure and to facilitate rotations by means of a calotte and a concave lower part.

The flat sliding surface between the top of the calotte and a sliding plate accommodates longitudinal and transverse movements. Guide bars and a restraining ring are used to transmit horizontal forces.

Depending on whether the bearing is fixed, guided or free sliding, it accommodates vertical loads, horizontal forces, rotations and longitudinal or transverse movements.

Quality

Main reasons for the quality and durability of the bearings:

- Qualified and experienced specialised staff

- Sophisticated and reliable individual component

- High-quality materials: min. 8mm thick DR SLIDE sliding material, long-lasting silicone grease, etc

- Quality standard (certified to ISO9001)

Mode of operation

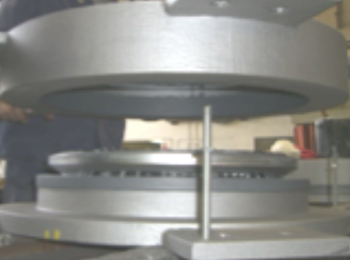

Free rotation is facilitated by the concave bored lower element, which is lined with DR® SLIDE sliding disc. A convex calotte forms the other half of the sliding pairing. With its polished, hard chrome surface, friction between the calotte and the concave lower element is negligible.

In the case of guided or free sliding bearings, a DR® SLIDE sliding disc is provided on top of the calotte and, in conjunction with the upper sliding plate, this permits bridge movement in one or two axes. In order to keep the frictional resistance to a minimum, a shear-resistant polished austenitic stainless steel sheet is welded to the underside of the sliding plate

Assembly of the bearing

Construction

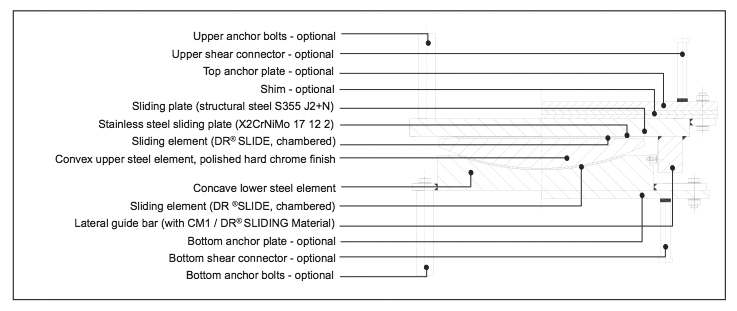

Principal components of the spherical bearings and materials used:

- S355 or S235 steel components

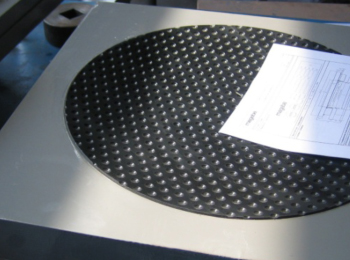

- High quality , DR® SLIDE, with grease dimples

- Sliding plate made of austenitic stainless steel sheet

- Convex calotte surface coated with layers of hard chrome

- Lubricant in the form of high quality certified silicone grease

Sliding plate of a spherical bearing

Corrosion protection

All exposed steel components are corrosion-protected. DOSHIN adjusts the corrosion protection to suit exposure conditions or according to individual customer requirements.

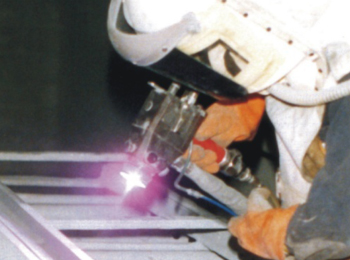

Standard corrosion protection (type C4 in accordance with ISO12944) is as follows:

- Sandblasting SA2.5

- Thermal spray galvanising (alternatively zinc rich primer)

- Epoxy coating

Thermal spray galvanising

Advantages of DR® SLIDE

DR® SLIDE bearings are suitable for all types of construction. In addition to excellent physical properties such as low wear and high compressive strength.

Resistance to aggressive chemicals and the effects of high-energy radiation are also excellent.

DR® SLIDE has excellent formability, making it easier to accommodate irregularities in the supporting structure and flatness deviations. Wear and local overstressing are less likely.

The high durability of the sliding material means that repair and maintenance costs are noticeably reduced.

Curved sliding surface of a spherical bearing

For more information, please get in touch with us at: 603-3290 5619 / 603-3290 5621 or click here for enquiry us.