We provide a complete range of expansion joint systems include Asphaltic Plug Joint, Compression Seal Joint, Combo Joint and Elastomeric Expansion Joints.

Through our technical support, we are able to offer a complete package of services to clients and will review a particular application from initial design to final installation to ensure the selection of the most appropriate and cost effective solution.

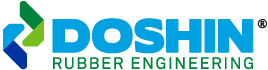

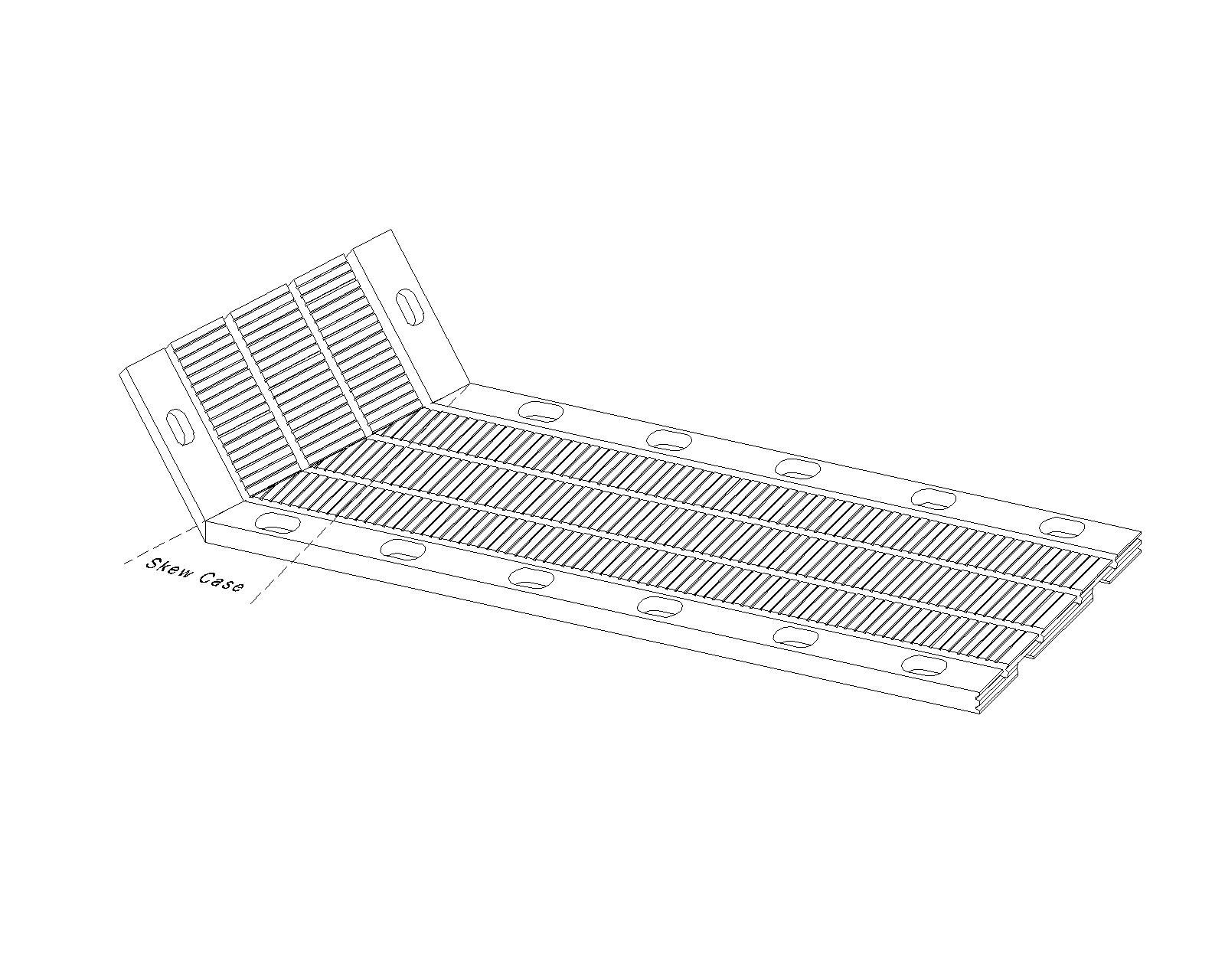

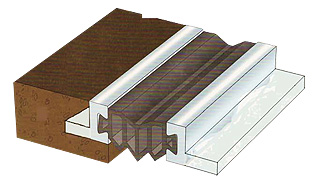

Elastomeric Expansion Joint

Doshin rubber bridge expansion joints comprise steel angles and steel bridging plate system encased in a flexible elastomer. Bridge expansion joint is capable of sustaining loads and movements up to 330 mm without damaging the surface or supporting structure during its working life. It has good riding quality and skid resistance that is not hazardous to all road users.

Advantages

- Extended durability

- Encased in corrosive resistant elastomer

- Water tightness

- Smooth wear resistant surfacing

We are capable of producing upturn according to customer requirement.

ELASTOMETRIC JOINTS ELASTOMER PROPERTIES

| Properties | Requirements | Test Method |

| Hardness | 60° ± 5°, Shore A | ASTM D2240 |

| Tensile Strength | 13 MPa, MIN | ASTM D412 |

| Elongation at break | 300 %, MIN | ASTM D412 |

| Adhesion Strength | 7N/mm, MIN | ASTM D429 |

| Ozone Resistance | No Cracks after 72 hours at 40°C exposure to 25 PPHM in air sample under 20% strain | ASTM 1149 |

| Compression set | 30 % , MAX after 22 hours at 70°C | ASTM D395

Method B |

Steel Properties

| Hardness | ASTM A36, BSEN S275JR, JIS SS400, or equivalent |

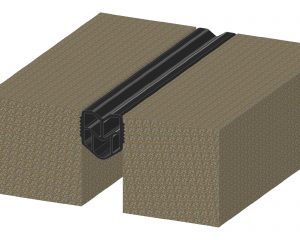

Compression Seals and Strip seals

Doshin has been manufacturing compression seals through contract manufacturing for many customer all over the world. The seal is a preformed elastic joint seal manufactured of neoprene or EPDM and installed with a lubricant adhesive. It is highly resistant to deterioration from exposure to weather, sunlight and impact. When properly installed, Doshin Compression Seal provides a permanent seal for any type construction whether in parking decks, buildings, or bridges.

Features Benefits

- Proven record.

- Cost effective solution.

- Ease of installation.

- No mechanical anchors or metal components. Installed by compressing the seal into place.

- Flat top surface.

- Non-serrated top provides a smooth riding surface.

- Neoprene or EPDM rubber.

- Provides excellent resistance to weather, sunlight, UV, and chemical (Neoprene only).

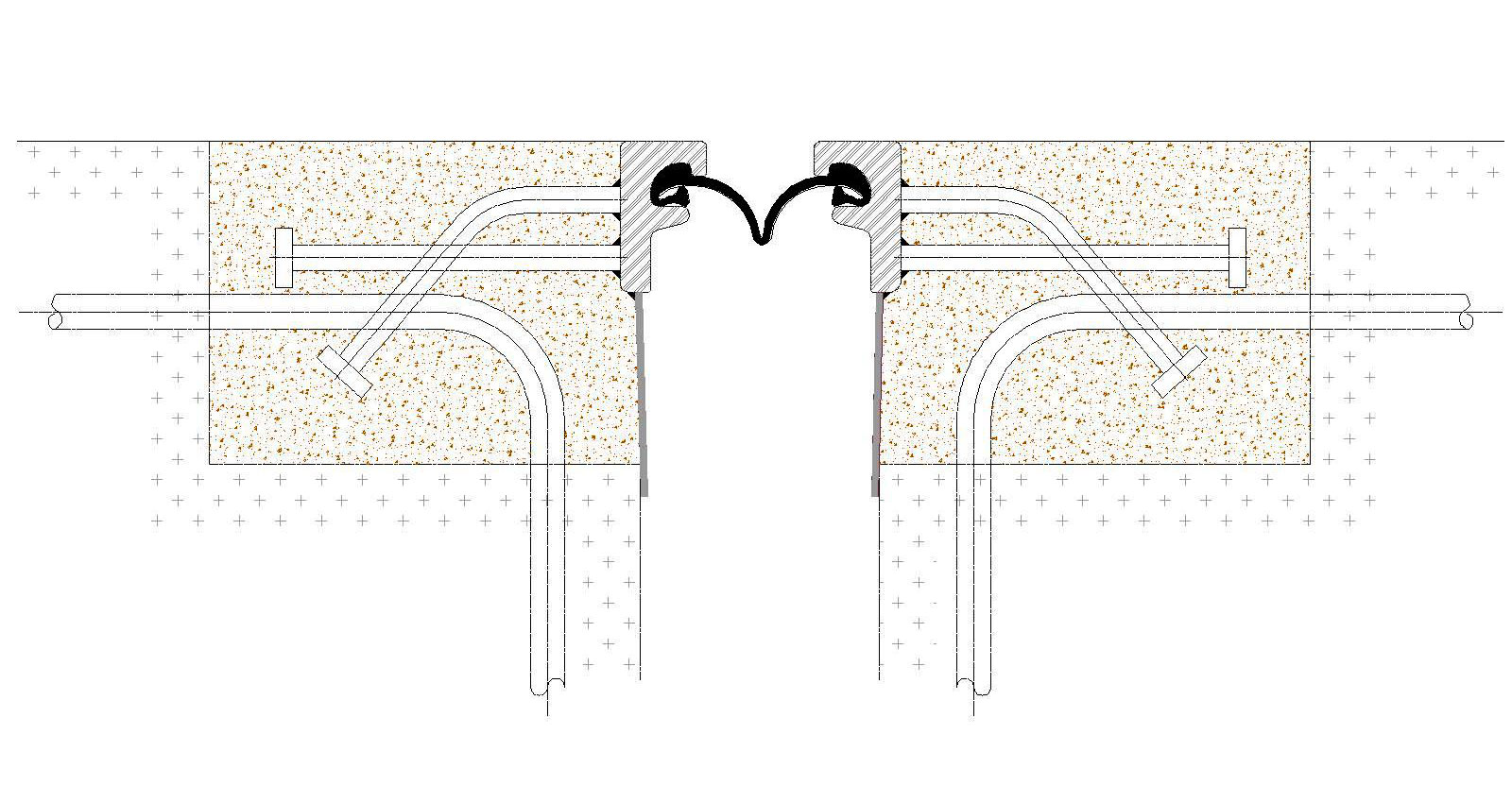

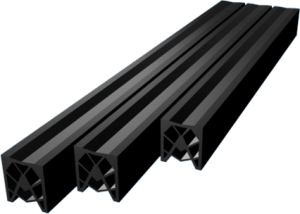

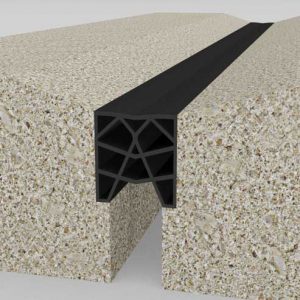

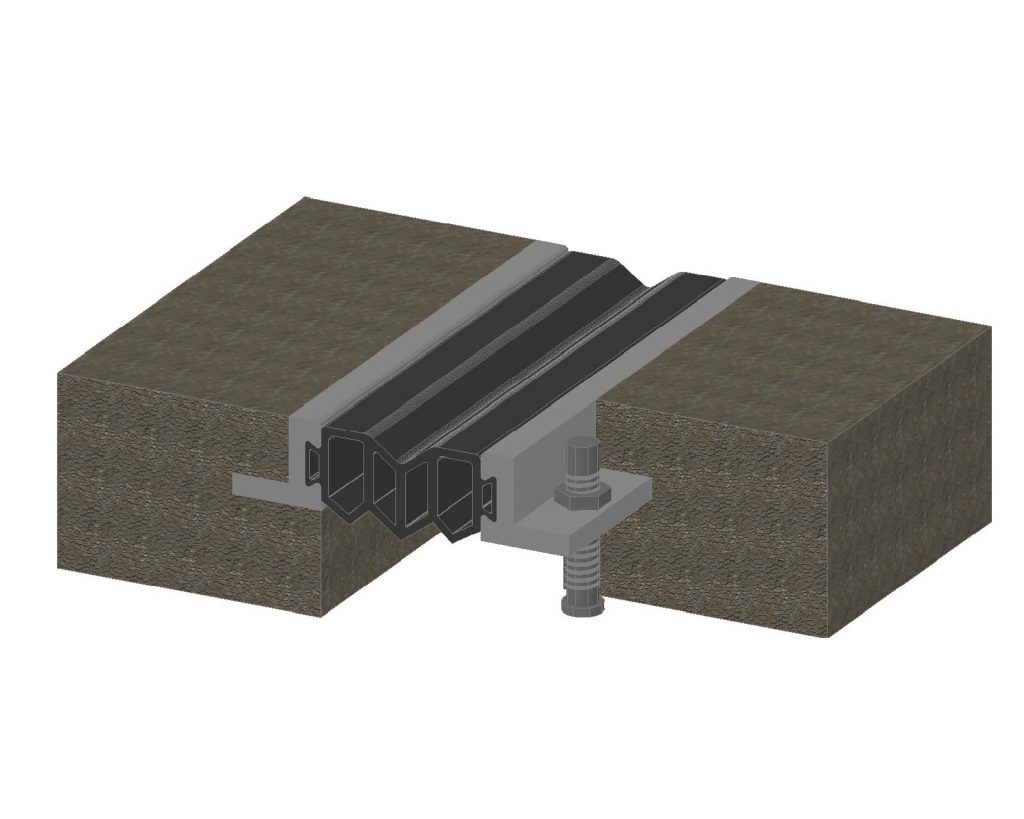

Combo Joint

DOSHIN COMBO JOINT system is an upgraded, modification and combination version from the common characteristic of anchorage elastomeric joint and rubber seal joint system.

DOSHIN COMBO JOINT system is composed of 4 main components:

1. Flexi seal (High-Performance Chloroprene Rubber)

2. Alloy rail (Grade 6061/T6)

3. Integrated anchorage system

4. Leveling screed (High strength epoxy mortar)

Features

- Excellent durability and easy installation

- Ability to cater for multi directional movement and loading

- Highly resistant to most kind of chemical and weather conditions

- Non-brittle and fast curing nosing

- Perfect waterproof properties

- Comfortable riding and anti-skidding

- Easy to suit any general changes in level or direction

Specification

|

Model |

Horizontal Movement |

Vertical Movement |

Construction Gap |

Standard Nosing WxD |

|

Combo 50 |

50 |

± 15 |

25 |

100×60 |

|

Combo 60 |

60 |

± 15 |

30 |

100×60 |

|

Combo 80 |

80 |

± 15 |

40 |

100×60 |

|

Combo 100 |

100 |

± 15 |

50 |

100×60 |

(All dimension in mm)

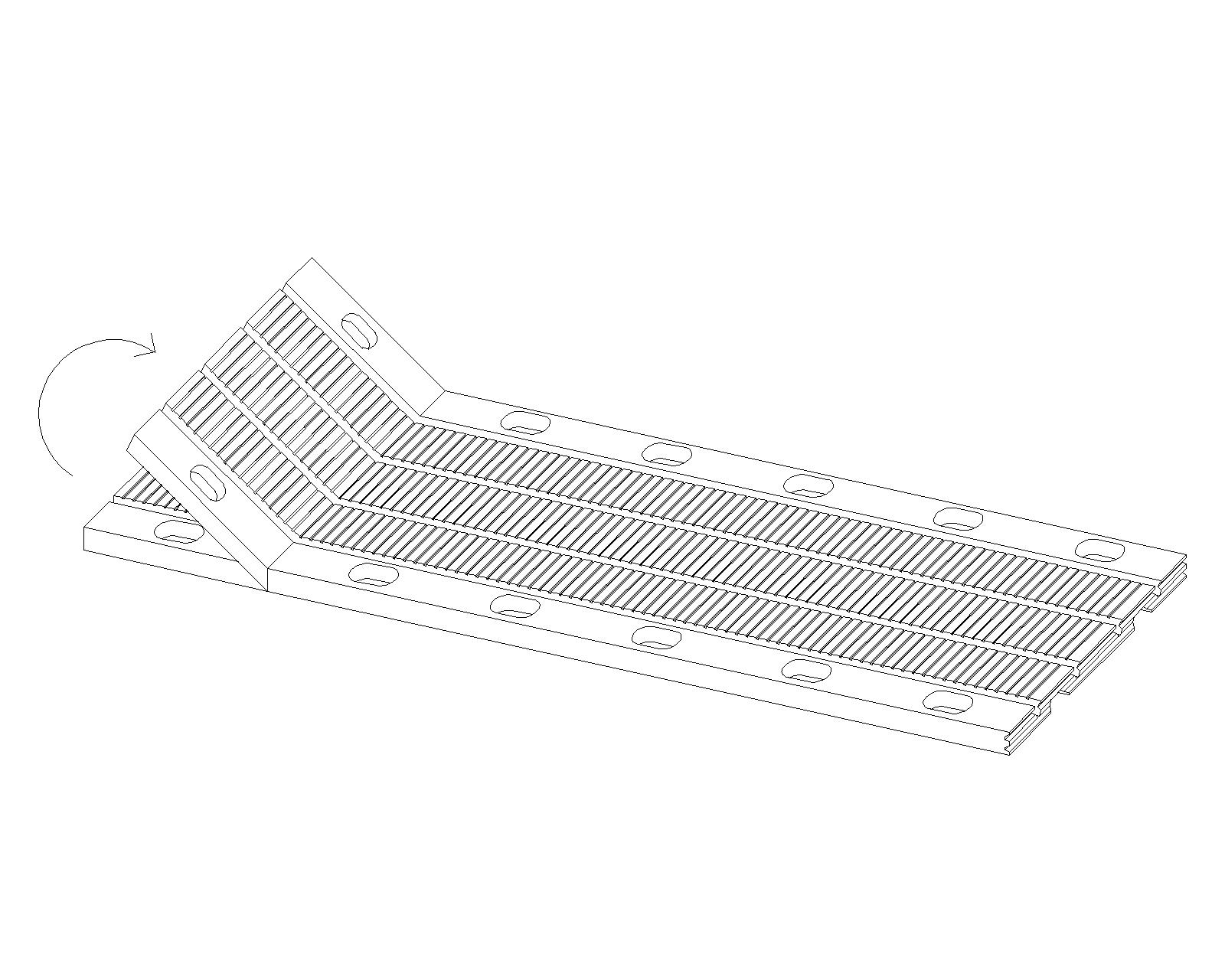

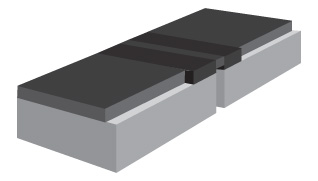

Asphaltic Plug Joint

Design Detail

|

Product Name |

Horizontal Movement |

Vertical Movement |

Recommended Joint Size |

Construction Gap |

|

DOSHIN |

±25 |

±1.5 |

500×75 |

25 |

|

AP |

±20

|

±1.5

|

300×75

|

20

|

(All dimension in mm)

Product Description

DOSHIN AP Joint Systems is an asphaltic plug joint which is suitable for low to medium movement capacity expansion joints on highway bridges and other selective structures. The maximum design movement for this joints are ±25mm on horizontally and ±1.5mm on vertically.

DOSHIN AP Joint System extends to the full depth of surfacing and is installed after the carriageway and verge construction has been completed. It performs by elastic and plastic deformation of the binder matrix through a combination of bridge deck movement factors and the nature of the traffic using the structure.

DOSHIN AP Joint System when installed will accommodate bridge deck movement factors. The normal movement capacity is attained in joint size at 500mm wide and not less than 50mm deep.

Binder Specification

|

Item |

Specification |

Test Method |

|

Penetration at 25°C |

ASTM D5 (1985) |

|

|

Softening Point |

>100°C

|

ASTM D36 (1985)

|

| Flash Point | >250°C | ASTM D92 (1985) |

| Specific Gravity at 25°C | >1.2 | ASTM D70 (1982) |

For more information, please get in touch with us at: 603-3290 5619 / 603-3290 5621 or click here for enquiry us.