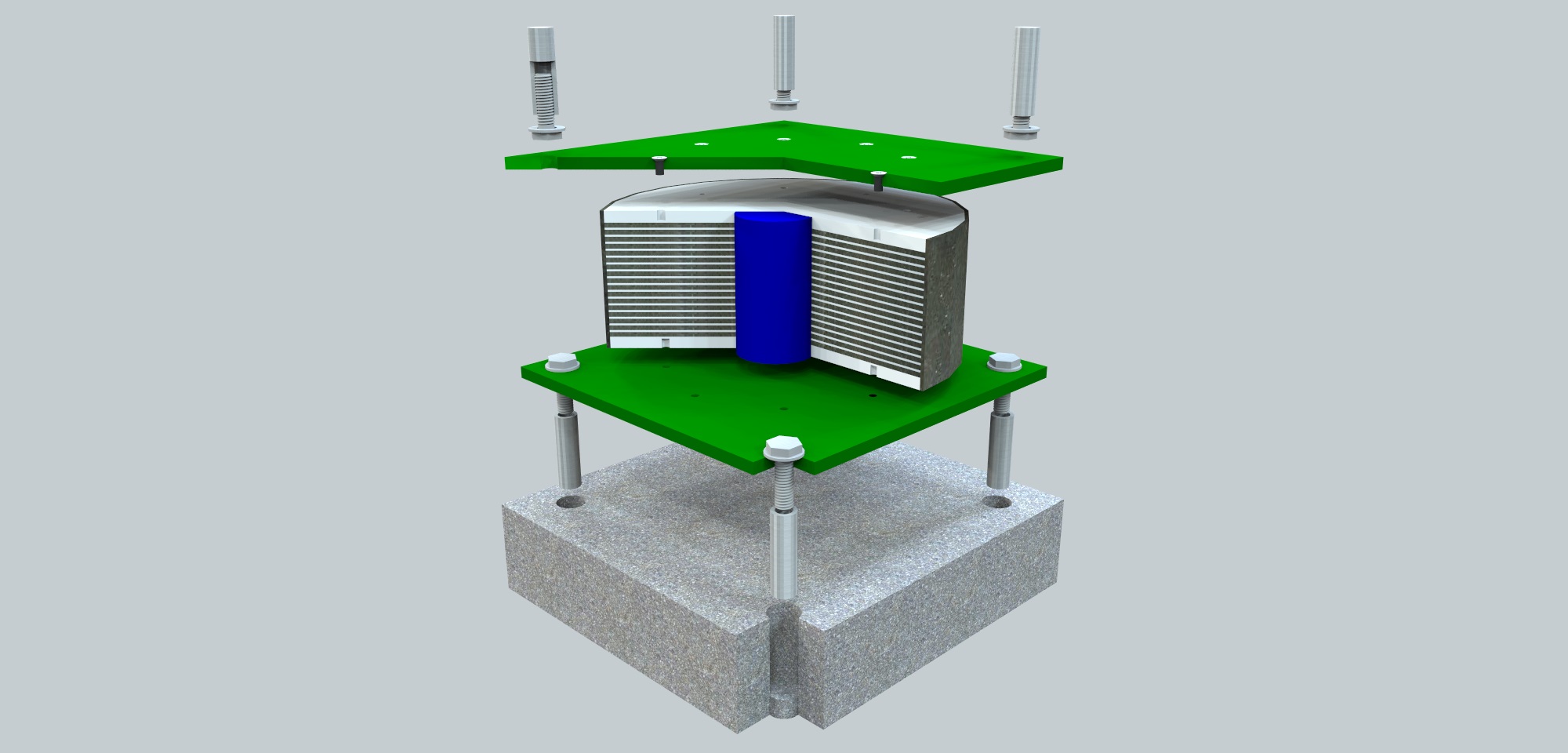

Doshin Base Isolation LRB lead rubber bearings work on the principle of base isolation and limits the energy transferred from the ground to the structure in the event of an earthquake. Base Isolation Lead Rubber Bearings (LRB) consists of a laminated rubber and steel bearing with steel flange plates for mounting to the structure. All isolators have an energy dissipating lead core. The rubber in the isolator acts as a spring. It is very soft laterally but very stiff vertically. The high vertical stiffness is achieved by having thin layers of rubber reinforced by steel shims. These two characteristics allow the isolator to move laterally with relatively low stiffness yet carry significant axial load due to their high vertical stiffness. The lead core provides damping by deforming plastically when the isolator moves laterally in an earthquake.

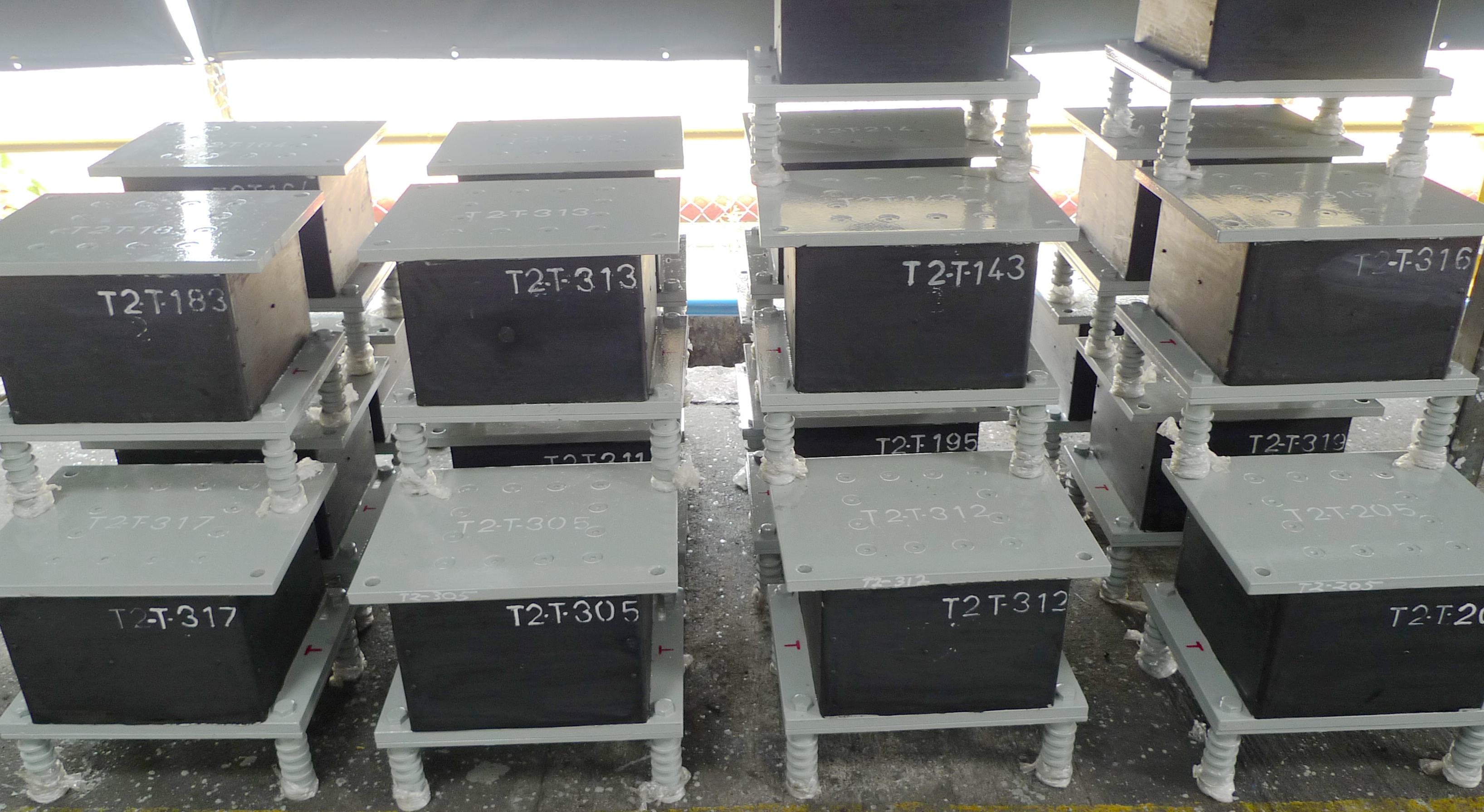

Production of LRB at Doshin

All steel for isolators are cut to exacting tolerances by laser. Both top and bottom end plates are machined by computer-controlled milling machines that give high production throughput and accuracy. All steel plates to be bonded to rubber shall be sandblast to remove all rust and sharp edges (rounded and chamfered), completely dip and thoroughly clean in degreasing agent, apply bonding adhesive primer, and apply bonding adhesive top coat and keep at the oven at control temperature before moulding.

Molding each bearing takes 8 to 48 hours depending on the size of the bearing. The curing phase is continuously monitored by temperature probe and PLC to ensure that the rubber is uniformly cured throughout the process

Material used for LRB

Rubber – the elastomer of the isolator will be natural rubber,all material testing shall be in acordance with EN 15129, or cross reference EN standard

Shim Plates- Shim plates and top and bottom end plates will be made from rolled carbon steel comformaing to ASTM A35 or equivelent confrming to EN 15129

Lead- The Purity of lead shall be establsihed by chemical analysis and shall confirm a minimum of 99.9% purity of the lead

Quality control and Testing

Doshin is able to perform full scale bearing size testing in house according to EN 15129: 2009 . Doshin lab is accredited by ISO/IEC 17025, fully equipped with full range of testing rig from 200kN to 50,000kN vertical load and 100kN to 5,000 kN shear load.

For more information, please get in touch with us at: 603-3290 5619 / 603-3290 5621 or click here for enquiry us.