Providing safety critical fender systems, Doshin has a strong focus on producing all fenders in-house ensuring highest quality products. All manufacturing is done strictly in accordance with Doshin or customers’ specifications, drawings, calculations and quality requirements, in order to ensure a safe and reliable fender system. Testing is done as per latest PIANC guidelines, for special test protocols, please contact Doshin for more info.

Doshin has an extensive proven track records of producing high quality rubber fendering products with our state-of-the-art test equipment including a combined shear and compression test press even for the largest fender sizes available. In addition to the performance verification testing, our certified laboratories check constantly all rubber batches used for the production of our high-quality fenders in order to verify compliance with material requirements for each single order.

Type of available Fenders are:

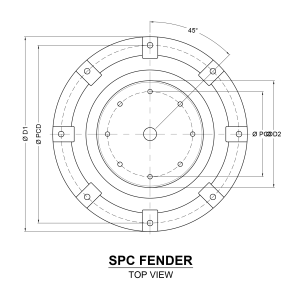

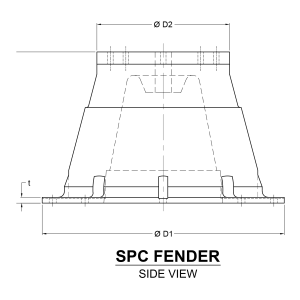

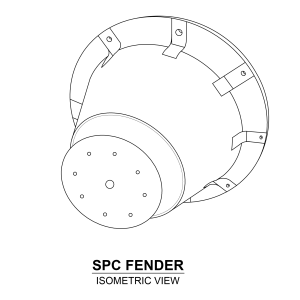

SPC Cone Fenders

SPC Cone fenders have a very complex shape, making the energy absorption and reaction force ratio effectively higher than Cell fenders of the same size. Advanced materials, cutting-edge technology and advanced testing facilities play a pivotal role in the success of the Super Cone Fender at Doshin Rubber Engineering.

SPC fenders have been in service at ports around the world for many years, and especially very popular at container terminals due to their durability and performance.

SPC Cone fenders are typically designed with frontal frame to allow for better distribution of stress across the hull surface and size are available between 300 and 2000mm.

Characteristics

- High energy absorption with reaction force ratio (E/R)

- Outstanding energy absorption per fender weight

- High allowable static load of fenders

- High shear stability to enhance angular performance

- High durability as the internal stresses are dispersed throughout the fender body

- Sophisticated and optimized fender geometry

- Optional overload stopper

Applications

- Container & Bulk Terminals

- Oil & Gas Terminals

- General Cargo Terminals

- Cruise Terminals

- Shipyard

- Ferry & RoRo Terminals

- Navy

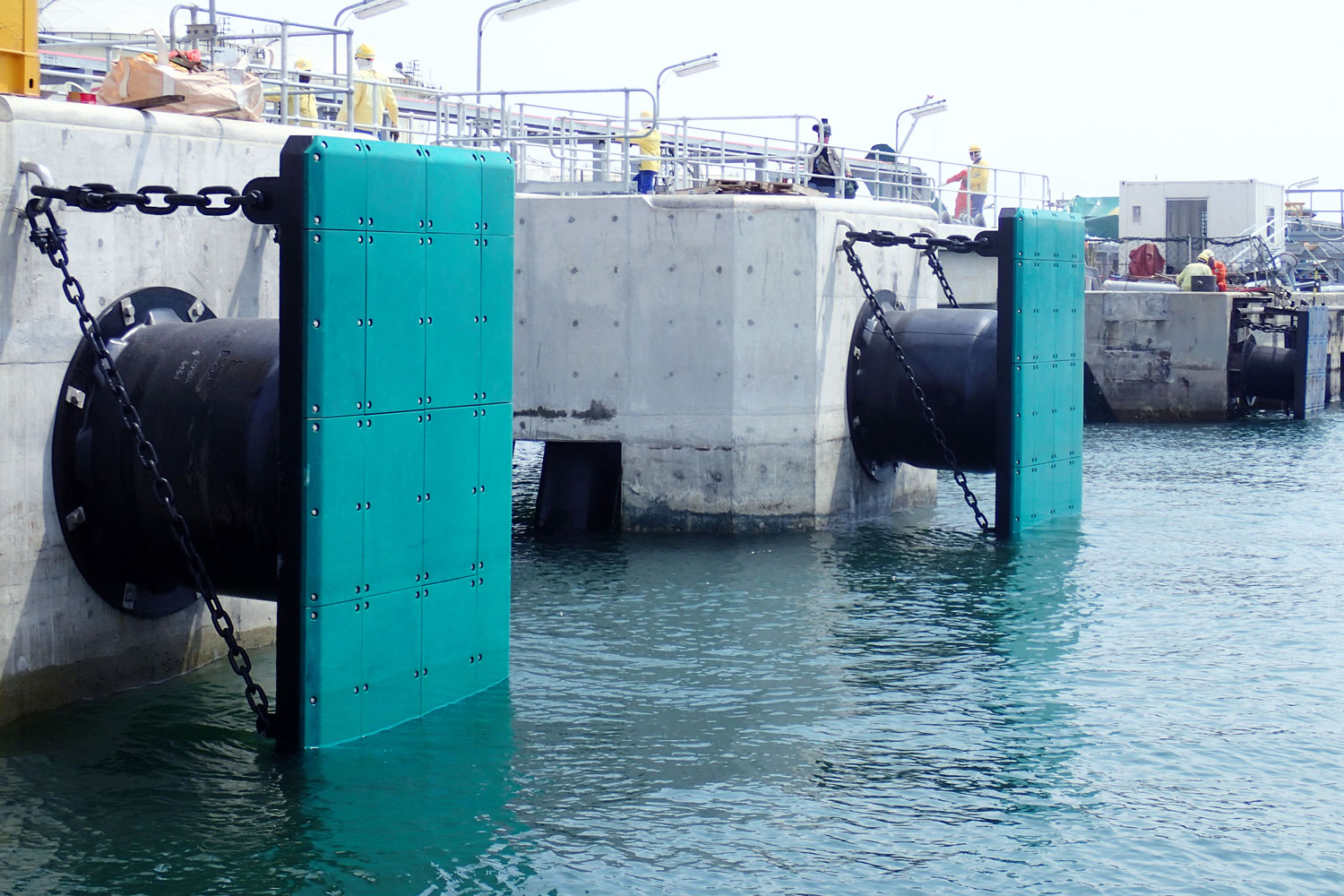

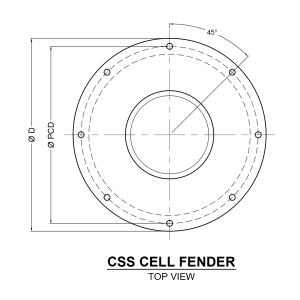

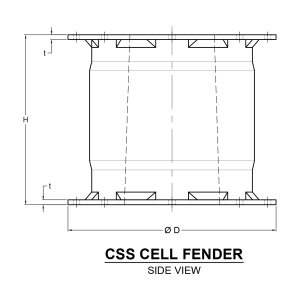

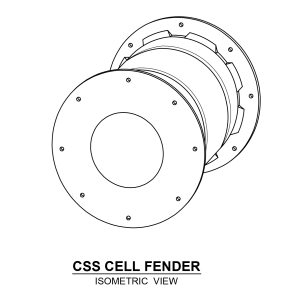

CSS Cell Fenders

Doshin CSS Cell fenders are unique, having a high energy absorption to reaction force ratio as one of its salient features. They are cylindrical in shape with two steel mounting plates firmly bonded to both ends of the main rubber column during vulcanization. It is designed to deflect in an axial direction up to 52,5% (design deflection).

Characteristics

- High energy absorption with low reaction force

- Excellent multi-directional angular performance

- Easy assembly & installation

- Good shear force resistance

- Very robust

Applications

- Container & Bulk Terminals

- Oil & Gas Terminals

- General Cargo Terminals

- Cruise Terminals

- Shipyard

- Ferry & Ro-Ro Terminals

- Navy

V Fenders

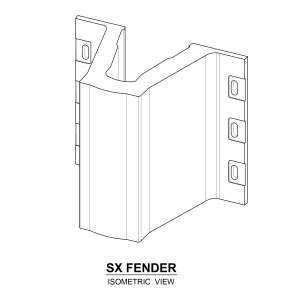

SX-type fender

It is the SX-type fender which is a narrow, excellent low reaction force and high energy absorption type. This is especially suitable for open-type piers with vertical piles and the like to which low reaction force type is advantageous to construction cost.

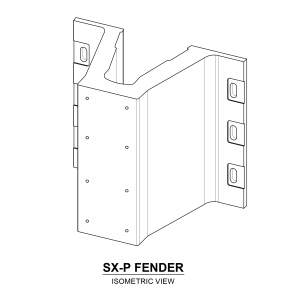

SX-P type fender

The use of impact-absorption plate and also can be equipped with UHMW-PE on the face of SX-type fender enables the plate to receive the local pressure from hull. The fender is so constructed that the local pressure is dispersed throughout the fender via the impact absorbing plate, damage to the fender by projections on the hull can be prevented, and stress is dispersed throughout the rubber part.

Both V Fenders (SX and SX-P) are available in standard heights from 250 to 1,000 mm, in standard length ranging from 1,000 to 3,500 mm.

Characteristics

- High energy absorption with relatively low reaction force

- High durability as the internal stresses are dispersed throughout the fender body

- Wide selection of sizes, length and energy capacities

- Can be installed both vertically and horizontally

- Ease of installation

Applications

- General Cargo Terminals

- Container Berth

- Berth for tug boats

- Multi-Purpose-Terminals

- RoRo ramps

- Shipyard

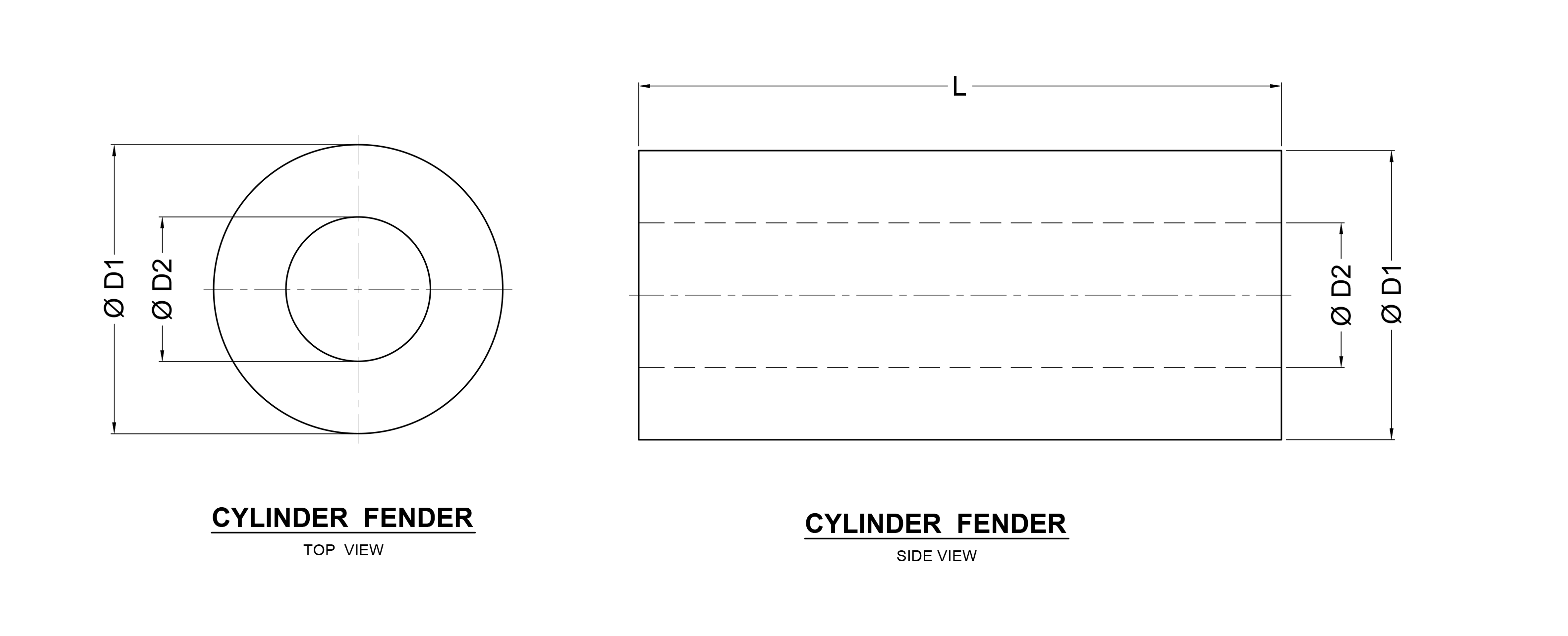

Cylindrical Fenders

Doshin Cylindrical Fenders are a simple and versatile marine fender system and can be easily installed. The Cylindrical Fenders’ proportional increase of reaction force and energy absorption all the way to the rated deflection is an advantage resulting in softer berthing.

Our Cylindrical Fenders are available by Moulding process to ensure it is compact, solid and reliable. Moulding size can be up to 2000mm. For small size, extruded process is also available upon requested.

Special dimensions and features such as pre-bending or jointing can be requested.

Characteristics

- Simple and economical design

- Special wear resistant rubber upon requested

- Very robust and simple design

- Easy to install

- Progressive Load deflection curve

Applications

- Bulk Terminals

- General Cargo Terminals

- RoRo Terminals

- Fishing and Workboat Berths

- Tug Boats

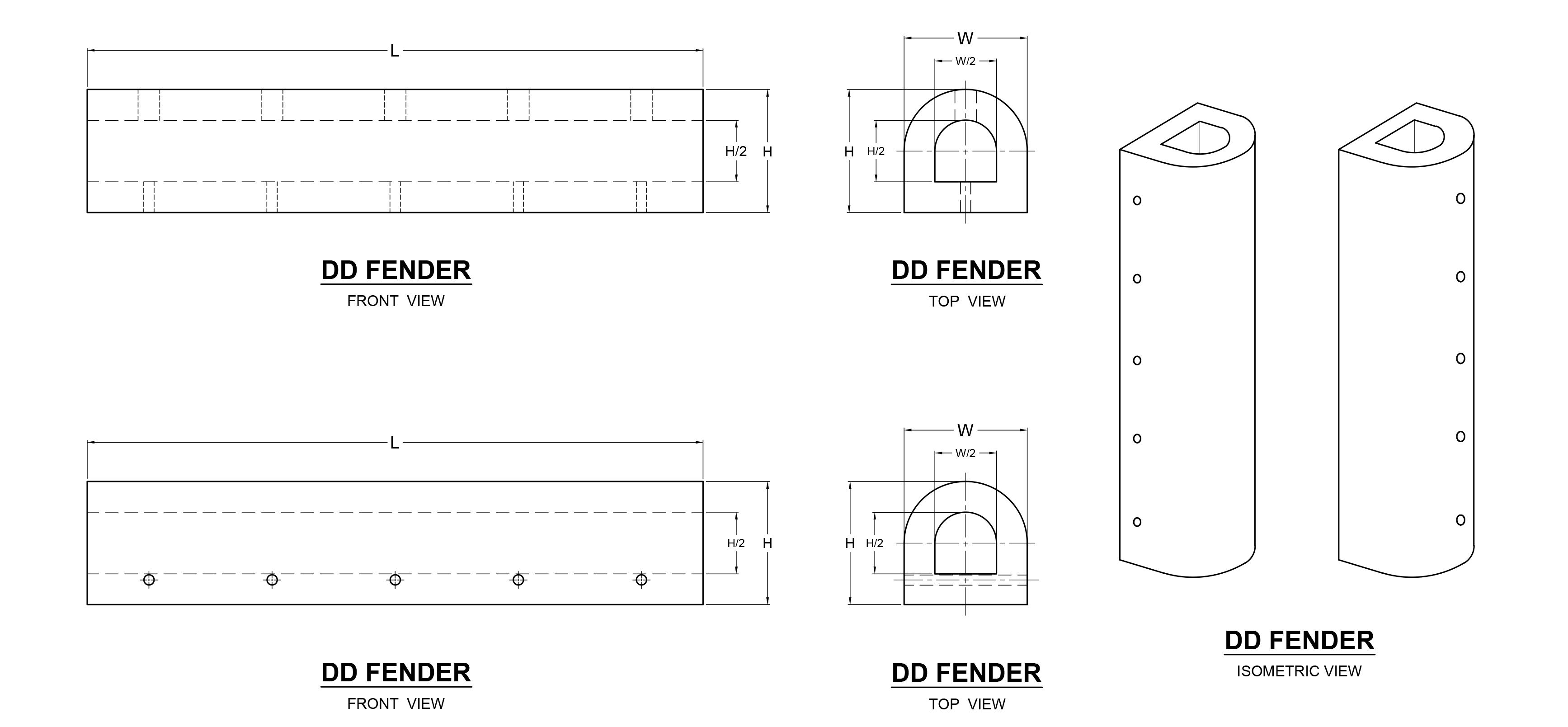

Rigid Fenders

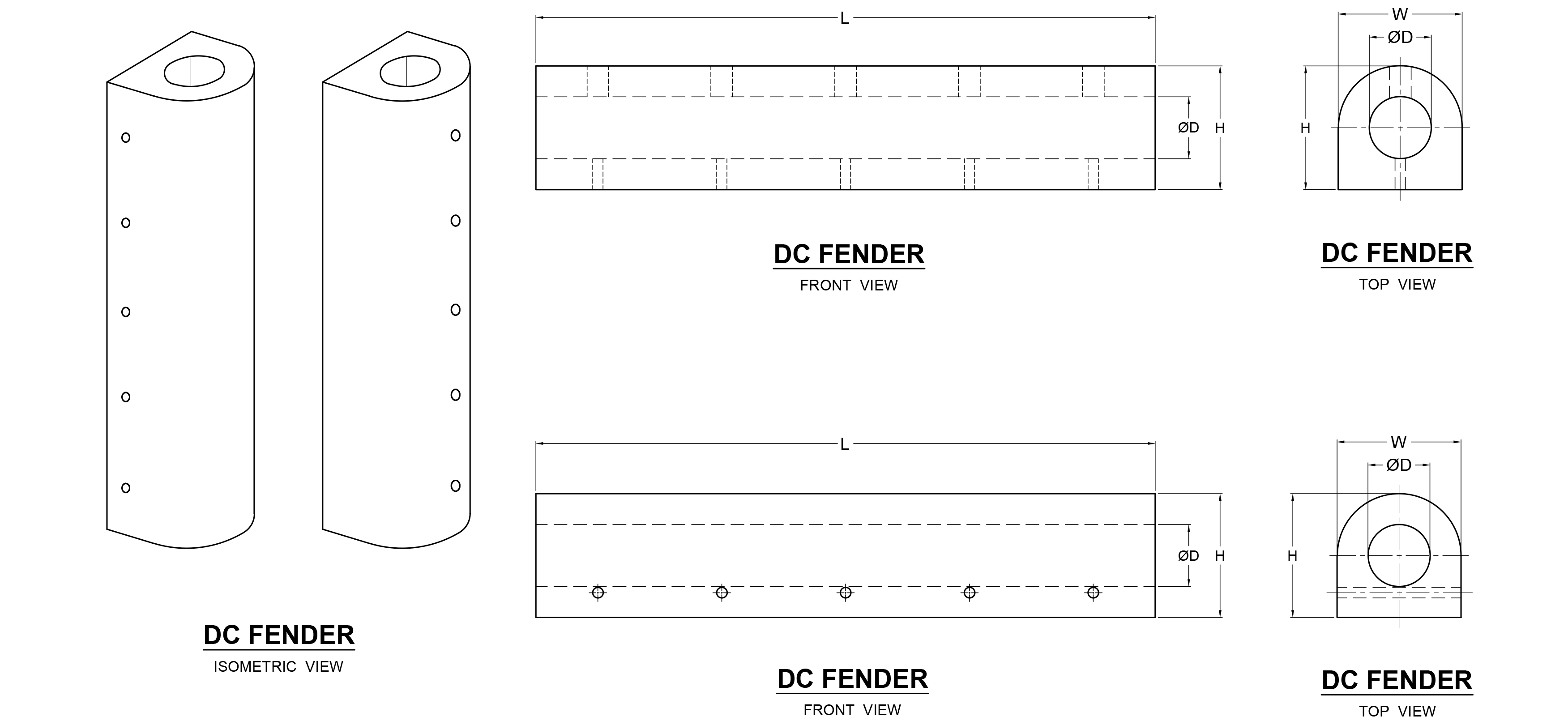

Rigid Fenders ( DD, DC, SC ) have a D or Square outer form and either a D shaped center (DD type) or cylindrical center bore (DC Fender).

Most of rigid Fenders at Doshin are by moulding process to ensure the best quality.

Rigid Fenders are available in standard sizes but can be supplied at odd size upon requested by moulding process.

Characteristics

- Simple & easy installation

- Customized sizes

- Wide range of applications

Applications

- Jetties and wharves

- Pontoon protection

- Multiple purpose fendering

- Tug Boats and Workboats

- Small boat berths

Komposite Fenders

Composite fenders are composites of rubber which provides resilience and UHMWPE with low friction and wear resistant properties.

The two materials are bonded with a special vulcanising method which is stronger and more reliable than a mechanical joint.

Composite fenders are manufactured through moulding process for best bonding strength between rubber and UHMW-PE.

Characteristics

- Combined energy absorption with low friction

- Resilient rubber

- Strong molecular bond

- Supplied cut and drilled for easy and quick installation if required

Applications

- Jetties and Wharves

- Mooring pontoons

- Landing platforms

- Tug Boats

For more information, please get in touch with us at: 603-3290 5619 / 603-3290 5621 or click here for enquiry us.