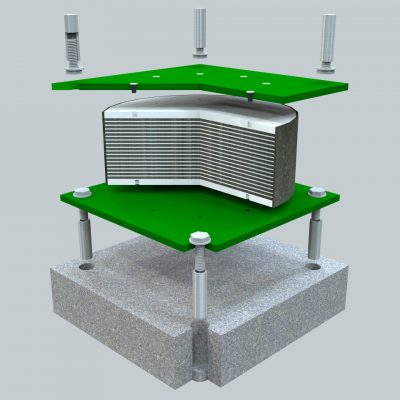

Explore our range of advanced seismic isolators, including the High Damping Rubber Bearings and Lead Rubber Bearings that are engineered to minimize structural damage during seismic events, offering enhanced protection for critical infrastructure by separating the earthquake induced ground motion from the superstructures. Additionally, our state-of-the-art Friction Pendulum Bearings ensure remarkable flexibility and reliable performance, setting new benchmarks for seismic resilience. Count on our innovative isolator solutions, designed to deliver exceptional safety and protection, even in the face of the most challenging seismic activities.

Base isolation offers important advantages over conventional protection methods because it reduces the earthquake forces transmitted into a structure. Thus it protects not only the structure itself but also the contents and secondary structural features. Such a capability is particularly important for buildings such as hospitals and emergency facilities that need to maintain full serviceability after an earthquake.

All steel for isolators are cut to exacting tolerances by laser. Both top and bottom end plates are machined by computer-controlled milling machines that give high production throughput and accuracy. All steel plates to be bonded to rubber shall be sandblast to remove all rust and sharp edges (rounded and chamfered), completely dip and thoroughly clean in degreasing agent, apply bonding adhesive primer, and apply bonding adhesive top coat and keep at the oven at control temperature before moulding.

Doshin seismic isolator-FRICTION PENDULUM bearings are based on the functional principle of a pendulum. They allow a structure to become horizontally displaced during an earthquake, with seismic energy being dissipated by the friction between various moving components. After the earthquake, the curvature of the sliding surface of the base causes the supported structure to return by gravity to its original position.